Paddy Taylor, MRMC Head of Broadcast, sees remote production as a practical route to core benefits, from reducing costs and improving efficiency to preparing operations for the future.

As a larger number of media and entertainment organisations begin to include sustainability among their priorities, remote production is gaining importance as a way to both deliver on environmental objectives, and meet economic goals.

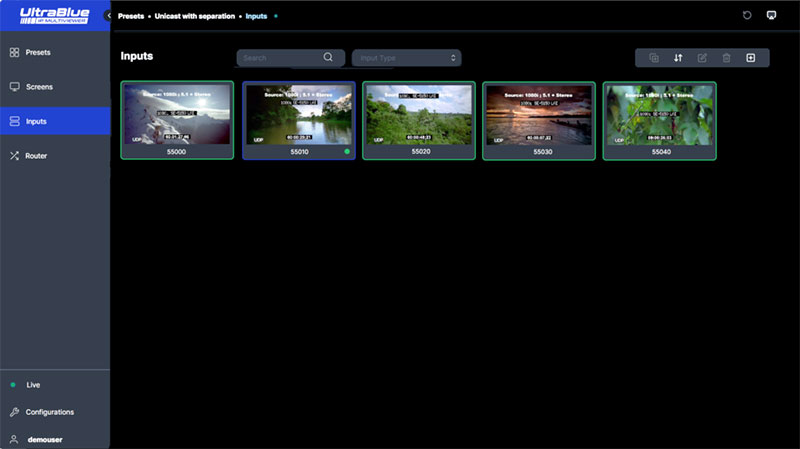

Teams are now able to manage studios from thousands of miles away, making the benefits of the model more apparent all the time. Instead of flying operators to every location, for instance, remote infrastructure and processes allow productions to reduce travel, accommodation and equipment transport requirements, cutting emissions and simplifying logistics in the process.

According to Paddy Taylor, Head of Broadcast, Mark Roberts Motion Control (MRMC), the drivers of this fundamental change of approach are mixed. “In legacy production processes, every stage of the process consumes energy and resources, often at a significant scale,” he said.

“Broadcasters and production companies are working to align with corporate ESG (environmental, social and governance) goals and emerging regulatory standards, and meanwhile the environmental impact of traditional workflows is coming under closer scrutiny. At the same time, consumer expectations are shifting. Audiences and advertisers now tend to favour brands that can demonstrate responsible practices.”

In this context, sustainable production is no longer only a matter of compliance or reputation – it is a practical route to some essential benefits, from reducing costs and improving efficiency to preparing operations for the future.

Critical Success Factor

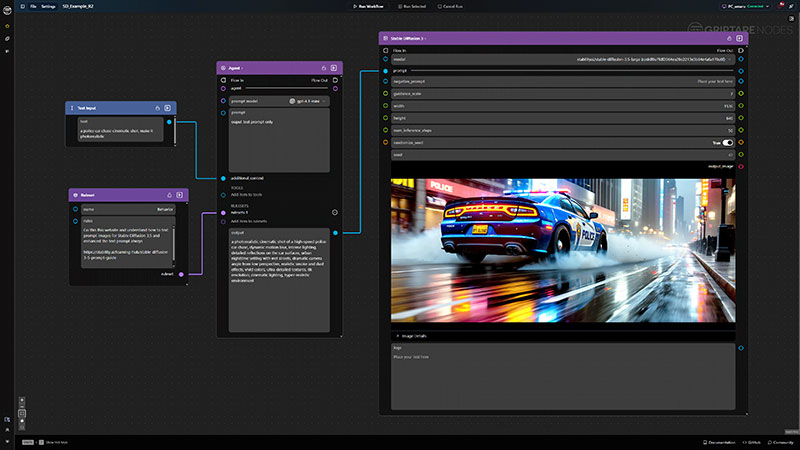

Paddy commented, “In examining the role of remote production, the underlying philosophy is not just about removing people from locations – it’s about rethinking production workflows to do more with less. As demand for content continues to grow across just about every platform, production teams are under pressure to increase output without expanding their budgets or environmental footprint. This makes efficiency a critical success factor, driving the need for smarter tools and more integrated operations.”

Automation also plays a central role in the industry’s shared efforts to become more sustainable. Features like automated tracking and centralised control of camera systems and production tools allow leaner teams to manage more outputs while maintaining high production quality. With the right systems in place, operators can scale their impact and avoid duplication of effort across what are becoming increasingly complex productions.

Taking Stock

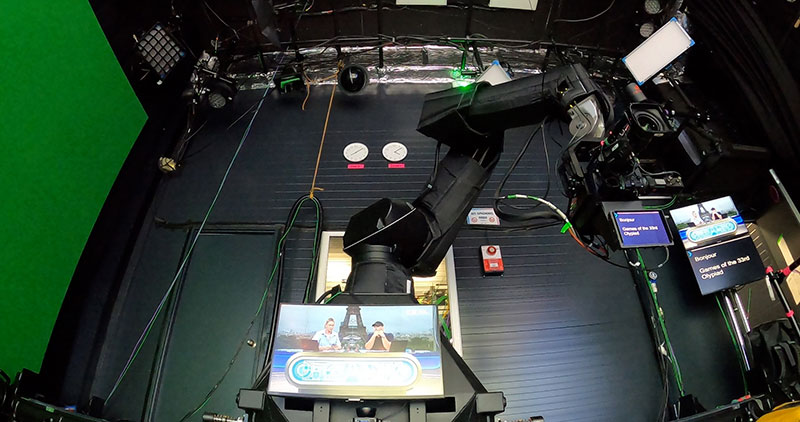

“Then there are remote-controlled camera technologies,” he noted, “whose precision and repeatability reduce the risk of errors or reshoots, which in live production can be especially costly. Taking the technology a stage further is the emergence of advanced robotic systems, which allow studios to maximise usage across different formats and time slots. For example, robotic arms used in live broadcasts can be easily reconfigured to produce stings, promos or commercial content during downtime, helping operators drive more value from existing space and resources.”

In the drive for physical efficiency, robotic systems typically require less space, fewer lighting resources and simpler rigging. When equipment does need to be transported, its compact and lightweight design helps reduce freight emissions. “Applied across a full production schedule, these marginal gains add up fast,” said Paddy.

Controlling Cost, Maintaining Quality

“None of this needs to come at the expense of cost or quality. With careful planning and the right technology mix, automation can maintain creative standards while driving down environmental impact. Don’t forget, the motivation shouldn’t be on reducing headcount; it should be about enabling skilled staff to work from fixed hubs or home bases, cutting the need for travel without compromising the final product.

“Remote production can also scale, and whether it’s adding new camera angles, increasing event coverage or managing simultaneous productions, these workflows can expand without a proportional increase in personnel or infrastructure. That makes growth more manageable and sustainable, even under tight deadlines.”

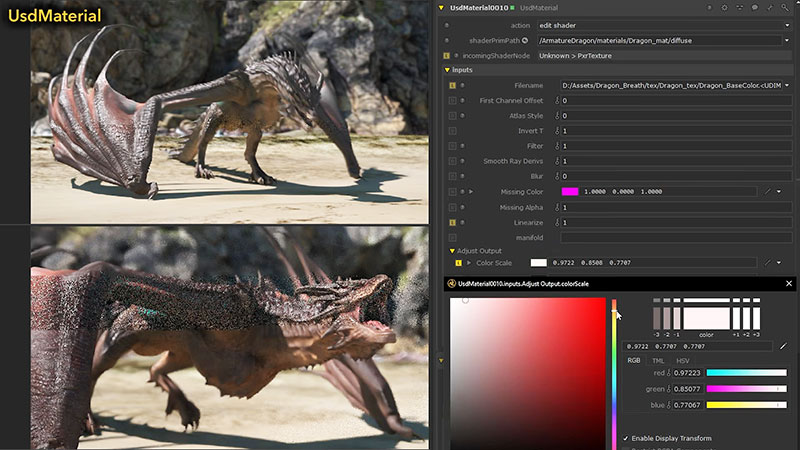

Driving progress at scale, however, requires collaboration. “When broadcasters, technology partners, facilities and regulators align around shared goals, real change becomes possible,” said Paddy. “This is especially true in virtual production, where integration is essential across lighting, graphics, robotics and control. With the proper coordination, these components can be planned and programmed as part of a highly efficient, end-to-end workflow.

Paddy Taylor, Head of Broadcast, Mark Roberts Motion Control

“Because AI and machine learning are now baked into these workflows more often, automated tracking and camera switching are becoming more commonplace. This results in lean workflows with efficient production that saves energy, time and money, all while reducing the carbon footprint.”

Aligning Efficiency, Savings and Impact

Of course, remote production still presents its challenges. Achieving the quality associated with traditional broadcast studios requires careful design and configuration. But with remote acquisition, where cameras are rigged locally and operated remotely, broadcasters can dramatically reduce on-site crew numbers and travel emissions without losing creative control.

Paddy commented, “Ultimately, delivering on sustainability objectives takes clear intent. Some broadcasters already factor environmental performance into vendor selection, while others still require a clear business case, where efficiency, savings and impact are clearly aligned. But for those willing to rethink legacy processes, the long-term financial, operational and environmental benefits are now well within reach.” www.mrmoco.com