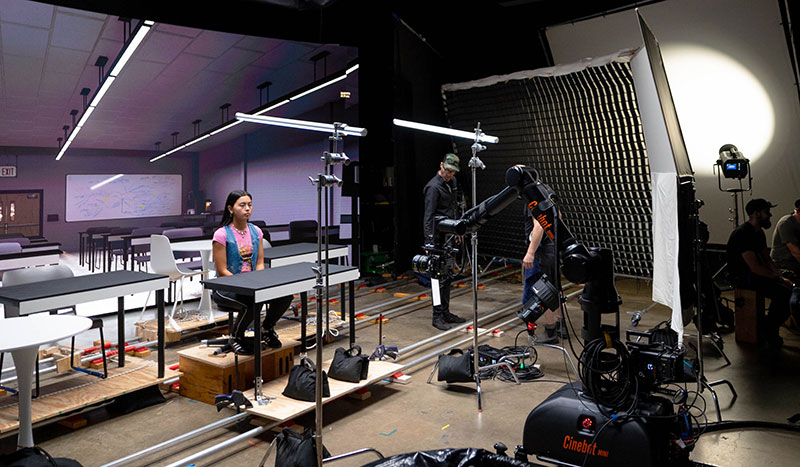

Drive-Thru Productions used Cinebot’s precise, versatile motion control features to digitally integrate shots into a one-shot commercial, and record three different aspect ratios at once.

Drive-Thru Productions recently partnered with video equipment rental house CineMechanics on a ‘Back to School’ campaign for Best Buy. A major challenge for both teams was creating invisible transitions between shots recorded in an LED volume, and those captured on-location. The goal was to blend the numerous digital and practical environments into one ‘continuous’ shot showing Best Buy’s essential products performing in each place, and meanwhile, to maintain consistent framing.

You can watch Best Buy’s spot here.

Consistency in the images would be a critical factor in post-production, when the editors and compositors planned to digitally integrate all shots into a single, smooth progression. To accomplish this, the crew put a new Cinebot Mini from MRMC to the test, using it throughout the shoot.

Lightweight, Portable and Strong

CineMechanics chose the Cinebot Mini knowing they would need the precision with which it can deliver repeated, frame-accurate camera movements, its flexibility in tight spaces, and its ability to handle complex VFX integrations in real-time. Its small size and lightweight design meant that it could be moved fairly easily between the LED volume stage and the various on-location shoots. Another advantage is that it uses 20-amp standard power in the volume, and on location operates on battery power.

The Cinebot Mini’s portable design made the on-set work much easier. The team could move quickly between the LED volume stage and various locations, and adapt to tight spaces. The Cinebot Mini’s option to run on battery power for up to 10 hours was significant during location shoots, making complex power setups unnecessary, and at the LED studio the crew could simply use standard 20-amp house power on the stage.

“The Cinebot Mini was exactly what we needed for this project – lightweight, portable and strong,” said CineMechanics owner Steve Speers. “Its precision and ability to shoot in tight spaces made it a valuable asset, particularly when transitioning between multiple locations and aspect ratios. Even though we had other robot options, the Cinebot Mini was the best choice for balancing flexibility and budget with creative demands.”

Aspect Ratios

As well as maintaining consistent motion and fluidity across the practical and virtual elements, the crew needed to fulfill Best Buy’s requirement to shoot the content in three distinct aspect ratios simultaneously – 16:9, 9:16 and 1:1. This added complexity to the camera setups. Not only did all three formats have to be framed precisely in a single configuration – it also had to be done without resorting to frequent adjustments, which would have compromised the motion aspect of the shoot.

Using the Cinebot Mini with the Sony Venice 2 camera and its Rialto extension system effectively met this requirement. By shooting in the camera’s full-frame ‘open gate’ mode, the post team had access to the sensor’s entire 6048 x 4032 resolution and could then crop the images to match the desired aspect ratios. Combining this resolution with the precise motion control of the Cinebot Mini, the team managed to capture all three aspect ratios in a single setup. The approach saved significant time and made sure that the client’s multi-format deliverables were consistent across every frame.

“The data we got from the Cinebot Mini was so clean that we didn’t need to rely on external motion trackers,” said Patrick Pierson, Director, Drive Thru Productions. “The ability to frame all aspect ratios – 16:9, 9:16, and 1:1 – within the same setup was crucial to delivering what Best Buy needed. The Cinebot Mini made what could have been a logistical nightmare into an efficient process.”

Separated Sensor Block

The Rialto, the VENICE camera’s Extension System, meant the crew could separate the camera body and image sensor block by up to 12m without affecting image quality. The separated sensor block, even with larger lenses, has a small enough profile for quick operation with motion-control rigs.

“The Cinebot Mini’s portability made much of this project achievable,” Alex Horner, freelance DoP said. “We could get shots in tight spaces that would have been impossible with larger systems. I could step in, adjust the camera and get the framing just right before locking in the moves. Using it with the Venice 2 and Rialto was an ideal combination for this campaign.”

The Rialto camera head has four assignable buttons that can be set to functions such as ND filter settings, REC Start/Stop and so on. Compatible with VENICE 2 using the 8K or 6K sensors, the head also has a sensor that detects horizontal and vertical tilt. This camera head tilt information can be checked when shooting at different angles and the same values are also recorded in the metadata and output through the camera’s SDI port, which is very useful for VFX applications.

LED Studio and Virtual Production Integration

Another significant challenge came when integrating the Cinebot Mini with the LED studio’s existing virtual production tracking system, which required taking precautions to avoid interfering with the intricate, continuous motion control. The integration posed a risk of accruing inaccuracies in tracking the movement between the camera and the LED wall, leading to potential issues with parallax in the displayed content, and synchronization later during camera transitions.

Solving this problem involved integrating the MRMC Advanced FreeD Sync Box, which is used to combine three different FreeD streams into one output for graphics systems, resulting in a single X, Y, Z output. That unification enhances accuracy and efficient control, and facilitates a direct connection between the Cinebot Mini, the LED wall and the camera. Streaming FreeD data between these elements synchronised all variables, making smooth parallax effects and accurate camera movements possible, even during complex sequences requiring multipass compositing.

CEO at Drive Thru Productions Mark Setterholm noted, “Cinebot Mini’s ability to work directly with the LED volume wall via Bluetooth for controlling parallax in the background imagery was a major advantage. Jacob Watson, our Cinebot Tech, handled everything so smoothly, it’s hard to imagine doing another shoot without this tool.”

Glare

Filming specific features of Best Buy products in different environments brought some extra complications. For instance, one sequence involved a reflective table that caused a distracting glare that altered the appearance of a silver laptop, creating an orange tint. Anomalies like this made it especially important to precisely control the camera’s movements as a way to preserve visual accuracy of all elements in the VFX plate shots that were captured throughout the shoot.

In this case, the team shot a VFX plate pass with a white card covering the reflective surface to prevent the unwanted orange reflections in post-production. Owing to the Cinebot Mini’s ability to repeat frame-accurate movements, this plate shot was integrated with the original footage to produce the desired look.

Camera Moves with Flair

Flair 7, MRMC’s software used to design repeatable shots for camera motion control robotics also played a crucial role throughout the project. Its features such as move scaling, SFX exports and shot speed adjustments saved a lot of time. Flair’s move simulation capabilities allowed the team to test and refine each camera move in a 3D environment before execution, making sure that complex shots involving multiple passes and effects would be recorded on set as planned.

As well as setting up shots, Flair synchronised the cameras for the shoot so that each frame was captured in exactly the same way, essential for the compositing artists. Flair reads in the pulse signals of the film camera, synchronises to it, and then starts the move at the precise moment required for each repeat pass to line up. Flair can also import and export moves from other 3D software like Maya or Blender, making it simpler to integrate Flair into existing workflows.

The precision and versatility of Cinebot’s motion control features were were what Drive-Thru needed to manage the transitions between the project’s varied environments and aspect ratios, and its lightweight design and battery power option simplified the on-location shoots. The ability to handle complex camera moves and integrate with virtual production setups made it possible to precisely align each frame, and achieve the expectations of their client. www.mrmoco.com